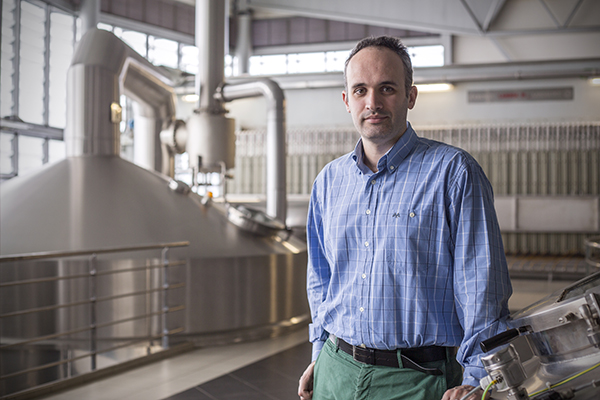

2014 hasn’t quite finished but we can already say that it has been a very special year at Hijos de Rivera. It’s been a year in which productivity has once again increased, something which our Production team has noticed as, now more than ever, they have worked flat out to meet the demand, always maintaining the highest quality standards of our beer. If that wasn’t enough, they have once again managed to find the time to develop a new edition of what has, undoubtedly, become a festive season classic, Estrella de Navidad (Christmas Estrella). One of the people who has been most involved in its production and that of all our beers is Luis Alvar, our Master Brewer. Before the start of a challenge-filled 2015, we wanted to sum up 2014 with him.

Estrella de Navidad has become one of the most awaited festive season products and every year it’s different. How do you do it? What’s the process involved in its creation?

From the moment this beer began to be sold (in the past it was exclusively produced for employees and as gifts for collaborators), there haven’t been able to be that many changes because, as you’ve pointed out, people have a specific type of beer in mind when thinking about this beer. Every year we make slight changes, mainly aimed at improving it based on people’s comments about the previous year’s beer. Besides this, there may be an original twist that the technical team can come up with. Depending on our objectives, we can slightly modify the process to obtain the beer we have in mind.

How is it different from Estrella Galicia Especial?

How is it different from Estrella Galicia Especial?

Mainly in the fact that Estrella de Navidad is a 100% malt beer and that always gives it a different profile with regards to other beers that have some kind of extra ingredient, neither better nor worse, just different, and it depends on people’s tastes. For this beer, we also use bitter hops produced in Galicia, which always gives our very personal touch to the finished product.

To work as a master brewer could be many people’s Christmas wish, but few people really know what your work involves. So, what does it consist of?

We dedicate most of our time to maintaining the process and avoiding departure from the established standard. As beer production is a biochemical process, there are many factors that could alter the final appreciation of the product. We are completely dependent on a microorganism, yeast, which is responsible for alcoholic fermentation and, as a living organism, it can produce different results from one day to the next if the conditions vary. We also depend on the state of raw materials which, being natural products, are not homogenous, and we have to change things in the process to avoid that these differences affect the product. Nowadays the process is completely automatic, and when working with many machines, there are always problems that have to be solved. To sum up, the day to day never bores us. Then there is the aspect of new product development, which is always the most rewarding, as we have the possibility of experimenting with ideas and developing our beers.

At this time of year we get together with our family, with friends that we haven’t seen for a while and we nearly always have a beer. Here at the Estrella Galicia brewery, you are in charge of making sure that there’s enough to go round on these days. Are you sure you all still like Christmas?

Yes, despite the huge number of parties and gatherings, this period is no worse than the activity on the beach in summer. Besides, personally, I like this festive period and the increased workload is not a problem.

How would you sum up 2014?

In general, I think positively. It’s been a hard year as our beer reaches an increasing number of places quickly, and we’ve had to increase the level of production beyond what we had expected. That means having to make new facilities at breakneck speed, which would have been impossible without the help and dedication of the engineering department. The maintenance department has also had to make an extra effort to ensure that everything is 100% in working order. Bottling has also been frantic and I can’t even imagine what logistics must have gone through. But, you know, we’ve made it and no-one has gone without beer, and if we continue to grow it’s because the effort that everyone has put in has meant that the product reaches the consumer, which is our main aim.

Just to put you on the spot. For a toast: cava or beer?

Beer, it’s important to try new things, and the product is worth it.